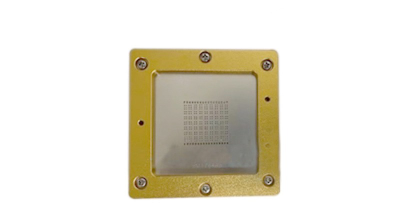

Universal chip tinning kit, the kit includes a diagonal 90*90 universal tinning tool and 27 90*90 tinning stencils. This kit is suitable for 99% of the SMD pins on the market, with accurate positioning, large load slot design, aluminum alloy frame, with a diversion slot, which is convenient for dumping excess tin beads.

Use tutorial:

1. Align the stencil hole with the chip pad, and lock the stencil screw

2. Dip a little BGA rework solder oil with a small brush, and apply a thin layer on the BGA pad (smear a little, otherwise it will cause continuous balls during reflow)

3. Put the chip coated with solder oil into the ball mount and cover it (be careful not to make the wrong direction of the chip)

4. Pour into the BGA solder ball

5. Gently shake the tin-planting ball seat, let the ball stick to the chip pad, and check whether there is a leaking ball. After completion, tilt the tin-planting seat to put away the ball, and the upper cover has a special place to place excess tin balls

5. Check the condition of the tin balls and whether there is any leakage of tin. After completion, remove the chip and heat it by flow soldering, so that the tin balls and the chip pins are welded together.

87763.68USD

87763.68USD 67.6USD

67.6USD 1.87USD

1.87USD 0.12USD

0.12USD 2941.64USD

2941.64USD 11.22USD

11.22USD 896.13USD

896.13USD 123.03USD

123.03USD 0.1USD

0.1USD 0.04USD

0.04USD 0.11USD

0.11USD

Favorites

Favorites History

History

Feedback

Feedback